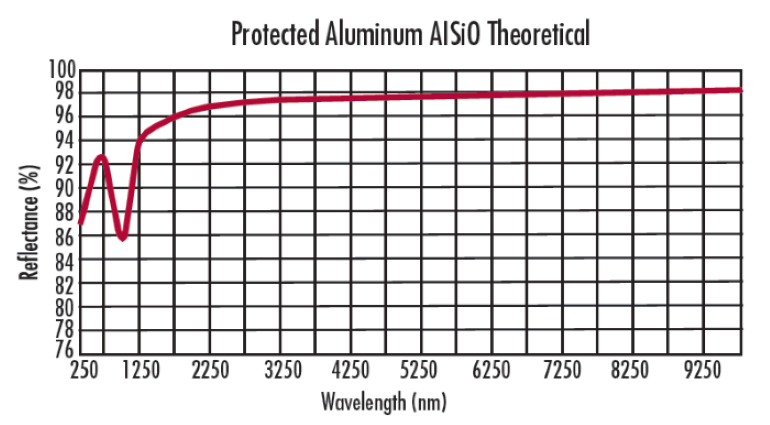

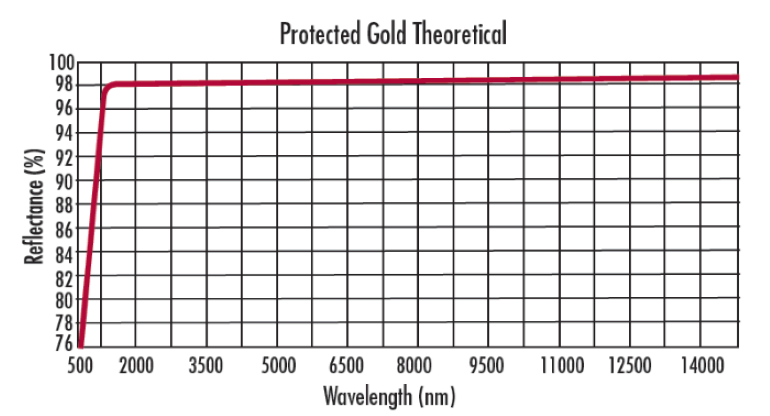

Metal Substrate Mirrors are available with either a protected aluminum or gold coating and are ideal for LWIR (greater than 2000nm) laser applications. Due to the 17.5nm roughness of the diamond turned surface, these mirrors may not be suitable for UV and visible applications that require low scatter. The backs of the mirrors are machined flat and are tapped with 3 holes for easy, accurate mounting. Metal Substrate Mirrors are aluminum substrate, diamond turned metal mirrors. These mirrors are available in five diameters: 25.4, 38.1, 50.8, 76.2, and 101.6mm.

1-800-363-1992

or view regional numbers

QUOTE TOOL

enter stock numbers to begin

Copyright 2025 | Edmund Optics, Ltd Unit 1, Opus Avenue, Nether Poppleton, York, YO26 6BL, UK

California Consumer Privacy Acts (CCPA): Do Not Sell or Share My Personal Information

California Transparency in Supply Chains Act